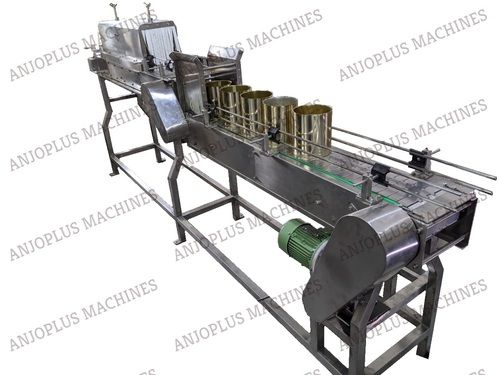

24 DS Seamer

Product Details:

- Noise Level 80 dB

- Operating Temperature 5C to 40C

- Frequency 50/60 Hz

- Function Type Seaming

- Power Source Electric

- Features High Seaming Accuracy, Easy Changeover

- Feeding System Automatic Can Feed

- Click to View more

X

24 DS Seamer Product Specifications

- Stainless Steel

- Seaming

- Electric

- For Seaming Can Ends

- High Seaming Accuracy, Easy Changeover

- 24 DS Seamer

- Automatic Can Feed

- 150-300 cans/min

- 5.5 kW

- 50/60 Hz

- 5C to 40C

- 80 dB

- 2600 kg

- PLC Control System

- Floor Mounted

- Round

- Yes

- Silver

- Can Seaming Machine

- Fully Automatic

- Variable Speed

- Yes

- Stainless Steel

- Automatic

- High Efficiency, Durable, Low Maintenance

- 380 V

- 2600 mm x 1250 mm x 2000 mm

- Three Phase

Product Description

24 DS SEAMER:CONSTRUCTION:

·Capacity 20 to 25 cans per minute.

· Arranged for motor drive less electricals,

Change parts comprising of Seaming Rollers, Can Slide Can Guide and Seaming Chucks

High-Precision Automated Seaming

Achieve accurate, consistent seaming results with the 24 DS Seamers advanced roller configurationfour seaming rollers and a dedicated first operation roller. Coupled with automatic can feeding and computerized PLC controls, this seamer delivers exceptional throughput and reliability, making it an ideal solution for high-volume production facilities.

Seamless Integration and Easy Maintenance

This machine is designed for seamless integration into modern, automatic filling lines. The centralized automatic lubrication reduces wear, and maintenance is simplified with tool-free panel removal. The robust construction ensures durability, while features like overload and short-circuit protection provide peace of mind for operators.

FAQs of 24 DS Seamer:

Q: How does the quick-change seaming head benefit production operations?

A: The quick-change seaming head design allows for rapid changeovers between can sizes or product types, minimizing downtime and increasing overall production efficiency. This feature is particularly valuable in facilities handling varying product lines.Q: What is the process for integrating the 24 DS Seamer with an existing filling line?

A: The 24 DS Seamer is compatible with automatic filling lines. Integration involves aligning the seamers automated can feed with your line, syncing operational speeds through the PLC control system, and performing trial runs to ensure seamless transitions between machines.Q: Where can this machine be installed, and what are its power requirements?

A: This floor-mounted machine is suited for industrial production environments. It operates on three-phase 380 V electric power, with a power consumption of 5.5 kW and supports frequency ranges of 50/60 Hz.Q: What maintenance process is recommended for optimal operation?

A: Routine maintenance involves monitoring the centralized automatic lubrication system and conducting periodic checks for wear on seaming rollers. Maintenance access is streamlined with tool-free panel removal, reducing equipment downtime.Q: When should the seaming head or rollers be changed?

A: Changeovers should occur whenever you switch to a new can diameter or if inspection reveals significant wear. Thanks to the quick-change mechanism, these adjustments are swift, minimizing the interruption to your production schedule.Q: How does the 24 DS Seamer ensure operator safety and product consistency?

A: The seamer is equipped with overload and short-circuit protection to safeguard both operators and the machine. Its PLC-based controls and precise roller mechanisms guarantee uniform seaming quality across batches.Q: What benefits does the centralized automatic lubrication system provide?

A: The centralized lubrication system autonomously distributes lubricant to key components, minimizing manual intervention, reducing risk of mechanical wear, and ensuring consistent, high-efficiency performance over extended periods.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email