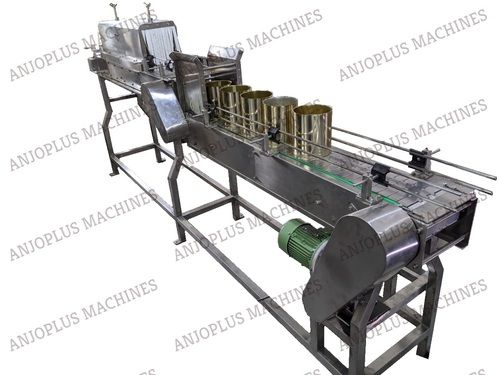

RECTANGULAR PULP COLLECTION TANK

20000 INR

Product Details:

- Power Source Electric

- Features Easy Cleaning, Leak-proof Construction

- Phase Single/Three Phase

- Noise Level Low

- Operating Temperature Ambient to 90C

- Function Type Storage / Intermediate Collection

- Machine Type Food Processing Equipment

- Click to View more

X

RECTANGULAR PULP COLLECTION TANK Price And Quantity

- 10 Piece

- 20000 INR

RECTANGULAR PULP COLLECTION TANK Product Specifications

- 50/60 Hz

- Collection Tank

- 150-350 kg (Depending on capacity)

- Top/Side Inlet

- Manual

- Pulp Collection Tank

- Manual

- Rectangular

- No

- 500-5000 Liters (Customizable)

- Stainless Steel

- Electric

- Easy Cleaning, Leak-proof Construction

- Metallic Silver

- Pulp Collection and Storage

- On Site

- 220-440 V

- Customizable, typically 1000 x 600 x 800 mm

- 1-3 HP

- No

- Ambient to 90C

- Storage / Intermediate Collection

- Food Processing Equipment

- Low

- Corrosion Resistance, Durability

- Stainless Steel 304/316

- Single/Three Phase

RECTANGULAR PULP COLLECTION TANK Trade Information

- 10 Piece Per Week

- 1 Week

Product Description

RECTANGULAR PULP COLLECTION TANK :

Function: For temporary collection of Mango pulp received from pulper.

Breif Spec:

- Stainless steel Inclined rectangular tank mounted for collection of pulp.

- Complete with two part top cover, inlet / outlet and drain connection.

- All corners rounded for easy cleaning and avoid contamination.

- Rigid legs supports

- M.O.C:- SS 304

- Capacity: 100 to 5000 Ltrs.

Customizable Industrial Collection Solution

This rectangular tank is built to match your specific process needs, with customizable dimensions, capacity, and internal lining options. The robust stainless steel construction guarantees superior durability and corrosion resistance, making it an ideal solution for industries seeking reliable, long-lasting pulp collection. Its manual control system and on-site installation offer intuitive operation and adaptability for any workspace.

Enhanced Performance and Cleanliness

Featuring a polished surface and weld-sealed joints, the tank resists both acids and alkalis while minimizing contamination risks. Its design supports easy cleaningcritical for food, pulp, and chemical processing. The bottom discharge valve ensures efficient draining, streamlining routine sanitation and maintenance. Industry-standard compliance (ASME/ISO) is available on request, fostering trust in quality and safety.

Efficiency Meets Flexibility

With flanged inlets/outlets, mobility-free installation, and options for internal lining, the collection tank adapts readily to your workflow. The top or side feeding system accommodates versatile process integration, while its manual operations allow clear and controlled handling. Noise levels are kept low for comfortable work environments, and electric power compatibility ranges from 220-440 V.

FAQs of RECTANGULAR PULP COLLECTION TANK:

Q: How is the rectangular pulp collection tank installed and used in industrial processes?

A: The tank is installed on site and remains stationary during use. It is integrated into pulp collection lines for storage, mixing, or intermediate holding. Inlet and outlet sizes can be customized and flanged for precise integration. Manual controls make it suitable for a range of industrial applications, such as paper, food, and chemical processing.Q: What maintenance is required for the pulp collection tank, and how easy is it to clean?

A: Maintenance is straightforward due to welded joints, a polished interior surface, and a bottom discharge valve for effective drainage. The design facilitates manual washing and minimizes residue, ensuring hygienevital for food and pulp industries. Any routine checks or cleaning can be performed quickly, keeping downtime minimal.Q: When should I request internal lining or standards compliance (ASME/ISO) for this tank?

A: Internal lining is recommended if your process uses aggressive or highly reactive chemicals, increasing protection and tank longevity. Requesting ASME or ISO standards compliance is advised when regulatory certification or enhanced safety assurance is necessary for your industry or export requirements.Q: Where can the rectangular pulp collection tank be customized to fit specific process dimensions or capacity?

A: Customization options are available directly from the manufacturer, enabling adjustments in dimensions (length, width, height), internal linings, inlet/outlet configurations, and capacity (5005000 liters). This allows seamless integration into existing systems, meeting space or capacity needs precisely.Q: What key benefits does this rectangular tank provide over circular or standard collection tanks?

A: Its rectangular shape enables more efficient use of space, particularly in compact facilities. The high-quality stainless steel construction ensures corrosion and chemical resistance, while its easy-clean surface and bottom drain simplify maintenance. Customizability and manual operation also support versatile industrial applications.Q: How does the tank resist acids and alkalis, and is it suitable for all pulp or food processing environments?

A: Constructed from stainless steel 304/316 and available with optional internal lining, the tank provides robust resistance to a wide range of acids and alkalis. Its smooth, polished finish and sealed joints further reduce the risk of chemical corrosion, making it suitable for sensitive environments like pulp or food processing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email