TWO STAGE PULPER

Product Details:

- Frequency 50 Hz

- Noise Level Less than 80 dB

- Features Low Power Consumption, Robust Construction

- Feeding System Continuous (Conveyor/Manual)

- Operating Temperature Ambient to 60C

- Machine Type Hydrapulper

- Speed Mode Variable

- Click to View more

X

TWO STAGE PULPER Product Specifications

- Automatic

- Mild Steel (MS)

- Three Phase

- Pulping & Screening

- Green/Grey

- Electric

- Rectangular

- Waste Paper/Pulp Sheets

- Variable

- Hydrapulper

- No

- 2500 kg/hr 10,000 kg/hr

- Custom/As per model

- High Efficiency, Continuous Operation

- 4200 11000

- 15 - 30 kW

- Ambient to 60C

- Pulper Machine

- Continuous (Conveyor/Manual)

- PLC Based

- Two Stage

- Less than 80 dB

- Floor Mounted

- 415 V

- Paper Pulping in Paper Mills

- 50 Hz

- Low Power Consumption, Robust Construction

- Yes

Product Description

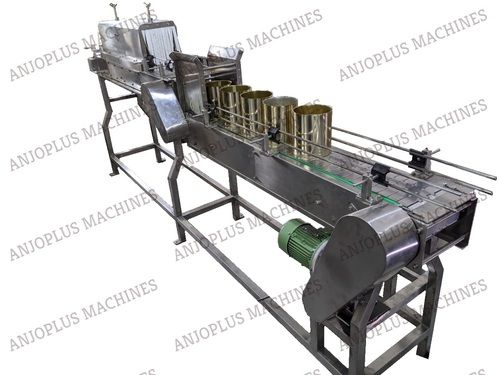

TWO STAGE PULPER :

Function: For extraction of pulp from Mango fruits.

Brief spec:

- Pulper mounted on Square tube Rigid structure with Coarse pulping screen dia. Perforation.

- Coarse Pulper complete with 2 Nos. of Brushes & 2 Nos. of Cutting Beater blades with adjustable height.

- Polypropylene base nylon Brushes caged in SS304 folded channels for extra strength.

- Hinged cover on top for easy cleaning after production batch.

- Lead screw arrangement in feed hopper for forward movement of fruits.

- Pulper complete Feed hopper, Seed discharge chute, Screen, Motor covers. etc

- Belt duplex pulley driven.

- Product outlet pipe for transferring coarse pulp in fine pulper.

- Fine Pulper will be same as coarse pulper but instead beater blades there will be 4 Nos. of Brushes with adjustable height.

- M.O.C:- SS 304

- Input Capacity: 100 to 5000 Kg / Hr.

Superior Pulping Efficiency

The Two Stage Pulper employs a unique design that facilitates effective disintegration and mixing of waste paper or pulp sheets. Its variable speed mode allows operators to achieve optimal fiber separation while maintaining low energy consumption. The integration of robust heavy-duty self-aligning bearings ensures smooth and silent operation, enhancing the longevity and productivity of the equipment.

Automated and Safe Operation

Equipped with PLC-based control systems, the Two Stage Pulper offers seamless automation, requiring minimal operator intervention. In-built safety mechanisms such as overload protection and emergency stops further safeguard both the equipment and personnel. Maintenance access is readily available through an inspection door, simplifying routine checks without disrupting operations.

Flexible Application for Paper Mills

With a customizable design, the Two Stage Pulper fits diverse facility layouts, handling capacities from 2,500 up to 10,000 kg/hr. Its compatibility with both manual and continuous conveyor feeding systems allows for adaptability in various pulping processes. Constructed from mild steel and available in green or grey finishes, the machine is built for reliability and aesthetic coherence within industrial environments.

FAQs of TWO STAGE PULPER:

Q: How does the Two Stage Pulper function in paper mills?

A: The Two Stage Pulper operates by continuously processing waste paper or pulp sheets, effectively breaking them down into pulp through high-speed rotor action and mixing. Its two-stage design allows for superior fiber separation and thorough mixing, making it ideal for paper mill applications.Q: What benefits does the PLC-based control system provide?

A: The PLC-based control system offers automated operation, precise process control, and immediate response to operational inputs. This system ensures consistency in pulping while reducing the need for constant operator supervision, thus improving overall productivity and energy efficiency.Q: When should maintenance be performed on the pulper?

A: Routine maintenance should be scheduled based on operational hours and manufacturer recommendations, but the inspection door facilitates quick checks and basic servicing without requiring system shutdown. Regular assessment of the bearings, belt drives, and rotor is advised to maintain optimal performance.Q: Where is the Two Stage Pulper typically installed?

A: This machine is designed for floor-mounted installation in paper mills or similar pulp processing facilities. Custom dimensions and its robust construction allow it to fit into a variety of plant layouts and industrial settings across India and abroad.Q: What process and raw materials does the pulper support?

A: It handles waste paper and pulp sheets, processing them at consistencies of 4%6%. The pulper is equipped for both batch and continuous feeding (via conveyor or manual methods), ensuring efficient fiber disintegration, mixing, and screening.Q: How does the machine ensure user and equipment safety during operation?

A: The Two Stage Pulper incorporates safety features such as overload protection, emergency stop functions, and a maintenance inspection door. These measures prevent operational hazards, protect machinery from damage, and promote safer working conditions.Q: What are the significant usage and efficiency features of this equipment?

A: With high throughput capacity, automated operation, low power consumption, and noise levels under 80 dB, the Two Stage Pulper is engineered for efficient, uninterrupted paper pulping. Its heavy-duty build and easy access for inspection contribute to reliable long-term usage in industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email